The test

Finally we got ready our layout and it's time to check it. How one can be sure about the connections?

There is an reliable electrical test, which ensures the right connections in the netlist.

Usually we use the test machine to test the boards, but this time we are testing the data. Having the

original PCB we run the test-program we created from our new layout and test the board for shorts and opens.

When any mistake shows up, will that mean, that the data is not OK.

A short on the test-machine means we have an open in the data. And opposite.

Quick reroute and the new layout is ready!

This test is a MUST to further avoid an unnecessary production of a failured PCB board,

which could have some netlist errors.

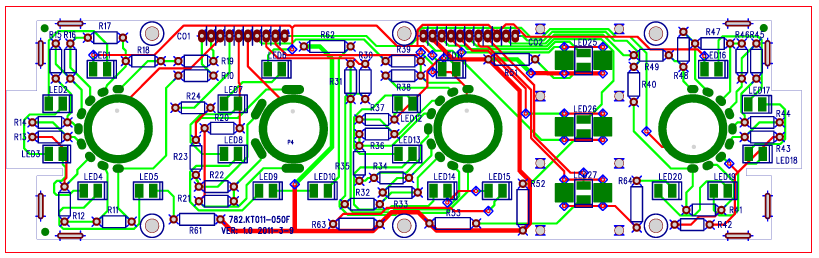

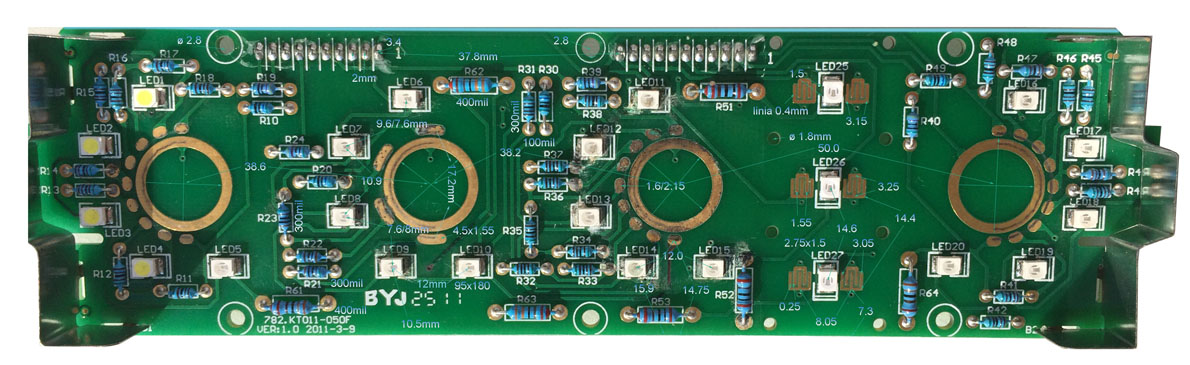

kt011

From the real board to the design..

A dimmensioning of the real board is the basic when creating the proper design.

Slide potentiometers, connectors and LEDs must be placed on same place as on the original board.

When misplaced the components will not fit into the case.